Robotics: Autobots Transform in the Offshore Energy Sector

Elaine Maslin

August 25, 2020

BladeBUG is a blade walking inspection robot, focusing on leading edge erosion inspection. Images from ORE Catapult.

“In a production plant, everything is pretty static and controlled. It’s easy to separate moving things from non-moving things and people from robotics,” says Alex Loudon, the UK’s Offshore Renewable Energy (ORE) Catapult. “Everything is linear, there’s no wind, waves or currents to get in the way. It’s so much easier to implement automation. When you think about offshore wind, it’s a different beast entirely, because of the operating environment.”

Hub-89: The Heriot-Watt University wheeled Husky robot used to demonstrate practical self-certification as part of an offshore inspection mission.

CUTHub 201

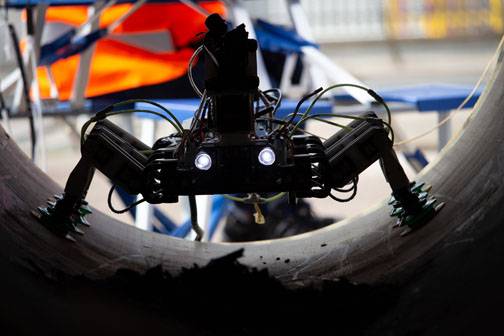

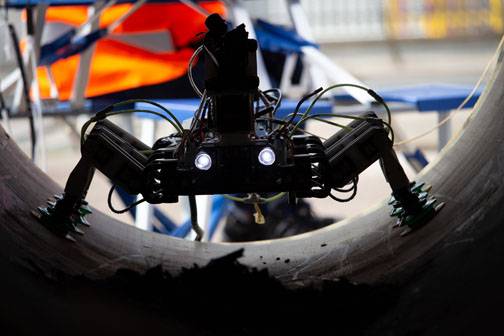

Prototypes of the OWCR have been trialed at onshore facilities that replicate offshore structures. Images from the Oil & Gas Technology Center.

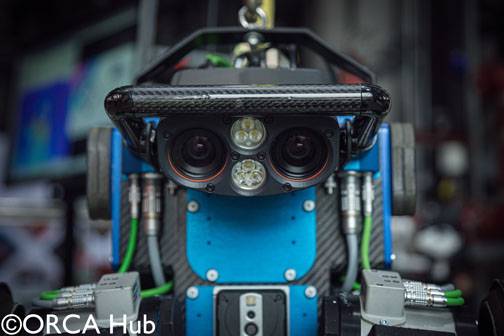

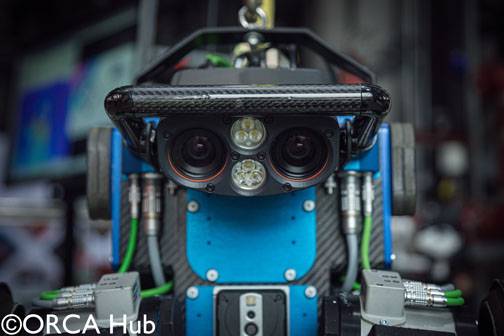

The University of Edinburgh’s quadruped ANYmal robot used to demonstrate obstacles navigation for inspection tasks using a thermal camera. Copyright ORCA Hub

OGRIP: The Oil & Gas Technology Centre is working with companies on the Offshore Ground Robotics Industrial Pilot (OGRIP) prototype, which is now what it calls the world’s first Offshore Work Class Robot (OWCR), shown here at SPE Offshore Europe last year. Photo from SPE Offshore Europe.